The Motor Drives The Rotor To Move At a High Speed Through The Transmission Shaft, And Generates Centrifugal Force To Shear The Material From The Narrow Gap Between The Rotor And The Stator At a High Speed, Forming a Strong Hydraulic Shear And Turbulent Flow, So That The Material Can Be Centrifuged And Squeezed At The Same Time. , Under The Coordination Of Comprehensive Forces Such As Grinding, Collision, Pulverization, Liquid Layer Friction, And Turbulent Flow Uniformity, It Can Be Fully Dispersed, Homogenized, Emulsified, Crushed, Refined, Mixed And Other Process Requirements. The More Layers Of Rotating Stators In The Working Cavity, The Larger The Shear Plane, And The Smaller The Gap Between The Rotor And The Stator, The Better The Effect. The

High-Speed Movement And Fast Shearing In The Narrow Gap Can Make The Immiscible Solid Phase, Liquid Phase, Gas Phase And Other Media Uniform, Fine, Dispersed And Emulsified In An Instant. After The Reciprocating Cycle, The Original Product Can Reach a Stable High-Quality Product

High-Speed Movement And Fast Shearing In The Narrow Gap Can Make The Immiscible Solid Phase, Liquid Phase, Gas Phase And Other Media Uniform, Fine, Dispersed And Emulsified In An Instant. After The Reciprocating Cycle, The Original Product Can Reach a Stable High-Quality Product

The Main Factors Of The Effect Of The Emulsifier

Rotor Linear Speed (Relationship Between Rotor Diameter And Rotational Speed) Gap Between Rotor And Stator Rotor Stator Layers And Shear Planes

Application:

Health production Industry: Ointment, Ointment, Lotion, Cream And Various Vitamins, Etc.: Daily Chemical Industry: Shampoo, Detergent, Cream/Paste, Toothpaste, Paraffin Solution, Hair Dye, Etc.; Adhesive Industry: Rubber Solution, Polyester Sulfide, Silicone, Hot Melt Adhesive, Polyurethane, Etc. Food Industry: Food Coloring, Chocolate, Filled Food, Syrup, Condiment And Various Additives, Etc.;

Health production Industry: Ointment, Ointment, Lotion, Cream And Various Vitamins, Etc.: Daily Chemical Industry: Shampoo, Detergent, Cream/Paste, Toothpaste, Paraffin Solution, Hair Dye, Etc.; Adhesive Industry: Rubber Solution, Polyester Sulfide, Silicone, Hot Melt Adhesive, Polyurethane, Etc. Food Industry: Food Coloring, Chocolate, Filled Food, Syrup, Condiment And Various Additives, Etc.;

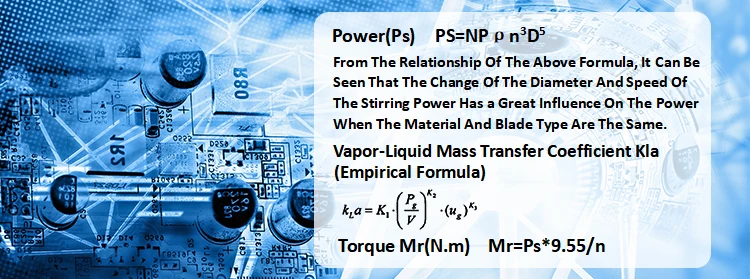

Confirm The Scheme Through The Above Multiple Calculation Verification

1. Determine The Appropriate Stirring Form And Size According To The Calculation Results Of The Medium And Stirring Purpose;

2. According To The Calculation Results Of Mixing Time, Shear Force And Blade Thrust, Determine The Rotating Speed To Achieve The Most Efficient Stirring;

3. If Dissolved Oxygen Stirring Is Required, The Blade Diameter And Rotational Speed Need To Be Checked Based On Factors Such As Gas Content, Gas-Liquid Mass Transfer Coefficient Kla(S-1), Etc.

4. According To The Determination Of The Above Conditions, The Stirring Power And Shaft Diameter Are Finally Determined, And The Reducer Is Selected.

5. Determine The Sealing Material And Structure According To The Medium, Pressure, Temperature, Speed And Other Working Conditions.